PTC нагреватели введение:

PTC нагреватель принимает источник тепла полупроводниковой керамики, это очень безопасно и контролировать температуру поверхности самостоятельно, так что он может работать без каких-либо регуляторов температуры и воды. PTC нагреватель долгий срок службы, энергосберегающий, высокая надежность, простота в установке, он широко используется в выпрямление волос и клее, подогреватель молока, сушка для обуви, массаж, тающий воск, coffe обогреватель, клеевой пистолет, ламинатор, паровой машины и так далее.

Технические параметры:

1. Нагреватель PTC может сам контролировать температуру, снижая риск перегрева, приводящего к возгоранию или повреждению оборудования.

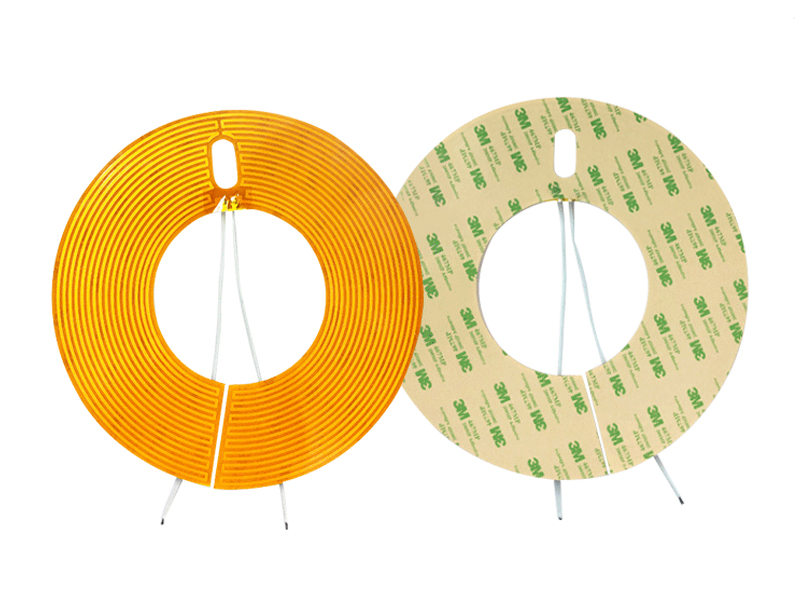

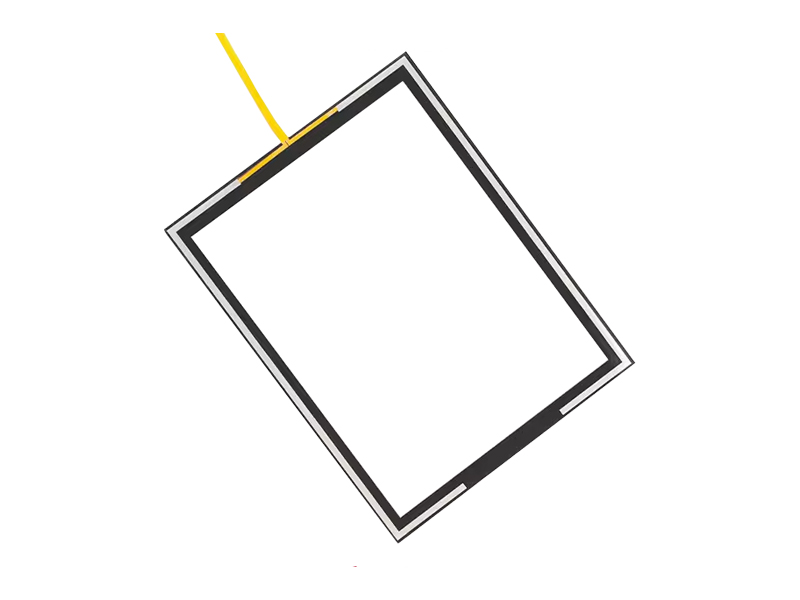

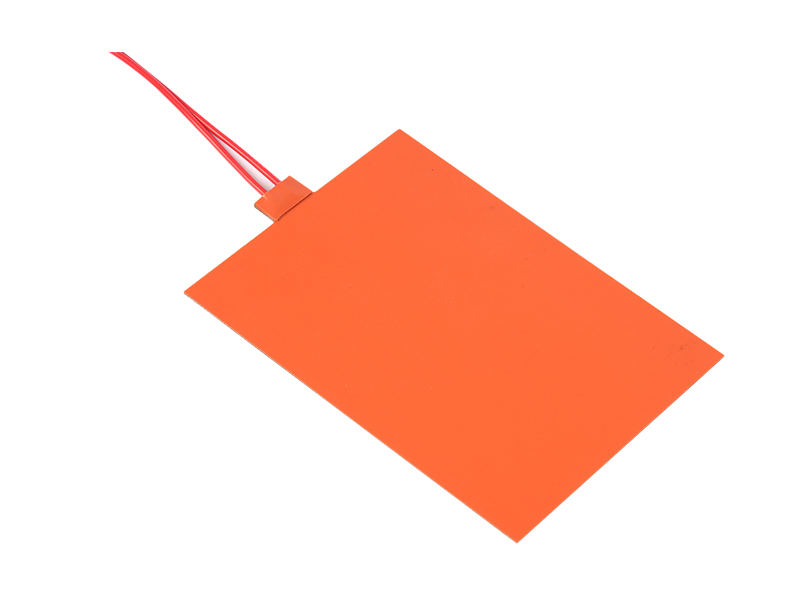

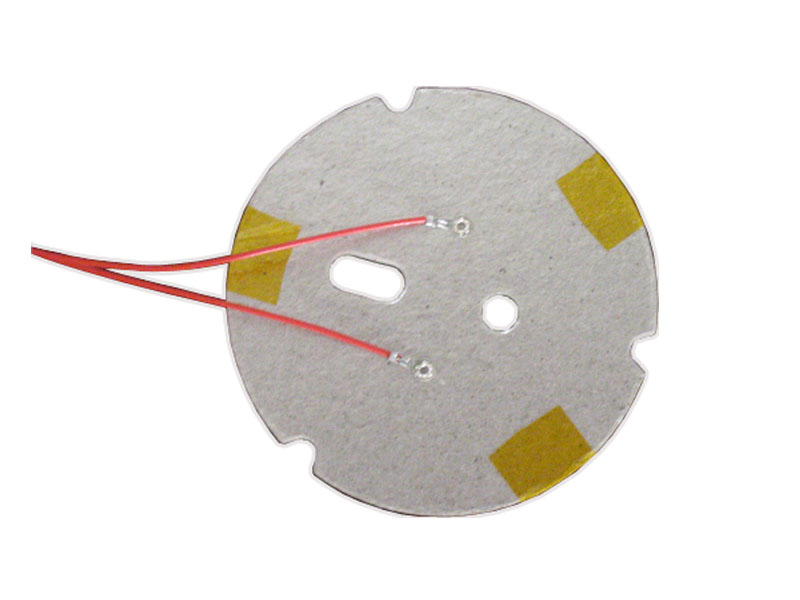

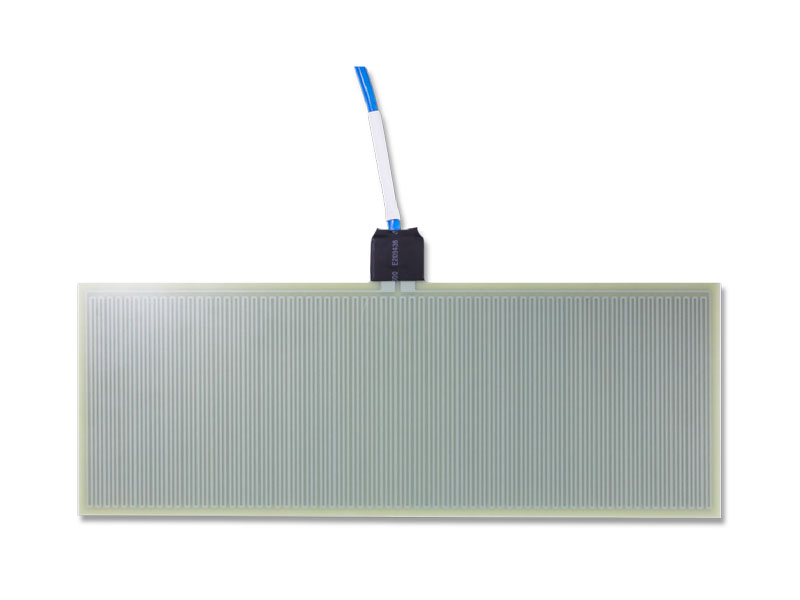

2. Нагреватели PTC могут быть различных форм и размеров.

3. Поверхностные материалы ПТК нагревателей включают алюминий, нержавеющую сталь, керамику и так далее.

4. PTC нагреватель может быстро достичь заданной температуры в течение короткого времени (от секунд до минут).

5. PTC нагреватель имеет относительно долгий срок службы около 50 000 часов.

Области применения:

1. Вентилятор для обогрева

2. Плиты для обогрева

3. Оборудование для сушки

4. Фен для волос

5. Для ног теплее

6. Дизельный обогреватель

7. Горячий клеевой пистолет

Q1: What is a PTC heater?

A: A PTC heater, also known as a PTC heating element, consists of a PTC ceramic heating element and an aluminum tube. This type of PTC heater has the advantages of low thermal resistance and high heat transfer efficiency. It is an automatic constant temperature and energy-saving electric heater.

Q2: What is the self-limiting effect in PTC heaters?

A: The self-limiting effect in PTC heaters refers to their ability to regulate temperature automatically. As the temperature increases, the resistance of the PTC material also increases, which limits the amount of current flowing through the heater. This results in a decrease in heat output, effectively preventing overheating and providing built-in temperature control.

Q3: What shell options are available for PTC Heating Elements?

A: PTC Heating Elements can be housed in various shells to suit different applications and environments. Some common shell options include plastic, aluminum, stainless steel, and ceramic. Each shell material offers specific properties such as durability, corrosion resistance, and heat dissipation, allowing PTC heaters to be tailored for diverse usage scenarios.

Q4: How do PTC heaters contribute to energy savings compared to traditional heaters?

A: PTC heaters are designed to draw full power at colder temperatures, allowing them to reach their threshold temperature quickly. As they achieve a steady-state temperature, they consume less energy than traditional heaters. This leads to lower utility bills and additional savings when using PTC heaters.

Q5: Can the shape, size, and resistance power of the PTC heaters be customized according to specific needs?

A: Yes, PTC heaters can be customized in various shapes, sizes, and resistance power according to customer requirements, offering flexibility to meet specific application needs.

Q6: What is the power density and how uniform is the thermal distribution?

A: PTC Heating Elements offer good thermal uniformity and high power density, typically ≥45 W/cm², ensuring efficient and even heating across the element.

Q7: How quickly can the PTC Heating Element heat up and compensate for temperature changes?

A: PTC Heating Elements heat up rapidly and provide quick temperature compensation. For example, they can reach temperatures of 600°C or more after operating at 500W power for 20 seconds, and the temperature of their components can reach 200°C or higher after 10 seconds at the rated power.

Q8: What safety features are included to prevent overheating and ensure safe operation?

A: PTC Heating Elements have built-in safety features due to their self-regulating properties. As the temperature increases, their resistance increases, which limits the current flow and prevents overheating, ensuring safe operation.

Q9: In what types of applications and environments can the PTC Heating Element be used effectively?

A: PTC Heating Elements are versatile and can be used in a wide range of applications, including household appliances, automotive heating, industrial equipment, and medical devices. They are effective in various environments due to their robust and adaptable design.

Q10: What is the lead time for the PTC heaters?

A: The lead time for the PTC heaters typically ranges from 2 to 4 weeks, depending on the complexity of the customization and current production capacity. For large orders or highly customized elements, the lead time might be slightly longer.